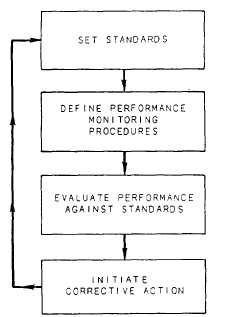

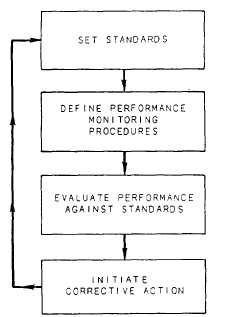

Figure 4-3.-Steps to effective control.

STEPS TO EFFECTIVE CONTROL

The steps to effective control closely resemble

planning and organizing steps. See figure 4-3. The

following are the four basic steps to controlling:

1.

2.

3.

4.

Set standards

Define Performance monitoring procedures

Evaluate Performance against standards

Initiate corrective action

Set Standards

To establish control over a process, you must first

decide what standards you will use for reference points.

Standards define the goals of your efforts. They express

recruiting targets, quality control goals, budget goals, or

flight schedules. These are quantitative standards: 14

recruits a month, zero defects, 10 percent spending

reduction, or all aircraft full mission capable (FMC) for

a sortie. Other standards involve qualitative goals:

sharp uniforms, fair selection boards, or improved

morale. Qualitative standards are much more difficult to

define and control than quantitative standards.

Define Performance Monitoring Procedures

The next step in achieving control is deciding how

to measure performance, what information to require,

and how to obtain it. Performance data maybe gathered

from personal observation, written and oral reports,

inspections, and automatic data processing (ADP)

products. Keep control procedures as simple and

cost-effective as possible. Ensure, however, that they are

adequate for the task at hand.

Evaluate Performance Against Standards

Compare performance data to established

standards. The results of this comparison indicate where

you are in relation to your goals. If everything is on

track, take a bow. If things are beginning to stray off

course or come unraveled, decide whether or not to take

corrective action.

Initiate Corrective action

If performance standards are not being met, you

should start corrective action. Examine your monitoring

system; is it accurate?

Do performance standards

accurately reflect mission requirements? Are your

standards too high or too low? If your monitoring

methods and standards are adequate, examine the

production methods and work force factors (morale,

leadership, and so forth). Can production efficiency and

effectiveness be improved? Is training up to speed? Do

leadership and supervisory ability meet your standards?

How about morale and environmental conditions.

Another possibility is poor planning or organization.

You must go to work and get things moving in the right

direction again. After all, that is what managers do!

EVALUATING YOUR CONTROLS

Most commands have four key areas of control:

financial, inventory, quantity, and quality. Use the

following criteria to evaluate your command’s controls:

Timeliness–Controls must provide timely

detection and correction of problems to minimize

wasted time and resources.

Accuracy–Accurate monitoring procedures

allow you to pinpoint potential problems for

correction.

Acceptability–Controls must be reasonable.

Unnecessarily stringent controls generate resistance

within the work force. When workers feel there is no

trust or fail to understand the need for controls, they may

circumvent the system. You are no doubt familiar with

the term gundecking. You may even know someone

who has been guilty of gundecking.

4-14