CAUTION

Snapback is extremely dangerous and has

caused severe injuries and death. The utmost

caution must be observed when working with

or around all synthetic lines.

WIRE ROPE

The basic unit of wire rope construction is the

individual wire, which is made of steel or other metal

and comes in various sizes. These wires are laid together

to form strands. The number of wires in a strand varies

according to the purpose of the rope. A number of

strands are laid together to form the wire rope itself.

Wire rope is designated by the number of strands

per rope and the number of wires per strand. For

example, a 6 by 19 rope will have 6 strands with 19

wires per strand. It may have the same outside diameter

as a 6 by 37 wire rope, which will have 6 strands with 37

wires of much smaller size per strand. The more wires

per strand, the more flexible the rope. Rope with fewer

and larger wires per strand is more resistant to external

abrasion.

The strands of the wire rope are laid up around a

central core, which may be only a single wire, a single

strand of wire, or hemp. A hemp core contributes

flexibility, cushions the strands as the wire rope

contracts under strain, and holds a portion of lubricant

for continuous lubrication. A wire core is stronger than

hemp and can be used where conditions, such as high

temperatures, would damage a hemp core.

WHIPPINGS

Whippings are bindings on the ends of rope that

keep the rope from unlaying. On line, whippings are

made with cord, such as sail twine or with marline. The

ends of all line must be whipped because of the frequent

need for passing the ends through rings and pad eyes

and for reeving them through blocks. Unlaid and frayed

ends of line are unsightly and unseamanlike and waste

many feet of line. Knots or backsplices in the end of a

line are not allowed, nor are friction tape or wire

whippings. Knots and backsplices will jam in a block;

friction tape will not hold for long; and wire may tear a

line-handler’s hands.

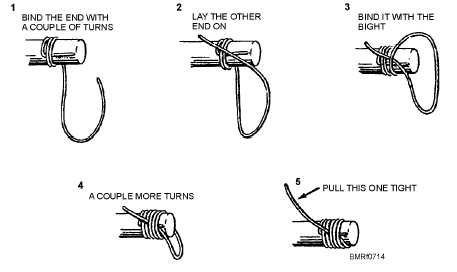

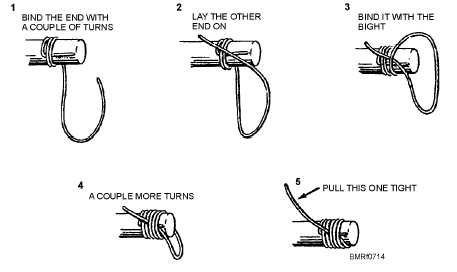

The most secure whipping is made with the aid of a

sail needle and palm. However, an excellent whipping

can be made without a needle if the procedure shown in

figure 7-14 is followed. First, lay one end of the

whipping along the line, bind it down with a couple of

turns, and snug up the edges. Then lay the other end on

in an opposite direction with the body portion of the

whipping, continuing with several more turns from the

bight of the whipping. The whipping length should be

about equal to the diameter of the line being whipped.

Snug up the edges and cut off the twine close to the line.

This type of whipping is a temporary one. If the line is to

7-14

Student Notes:

Figure 7-14.—Plain whipping a line.